bull nose end mill definition

Bull-nose end mills are often called corner radius end mills and are a combination of fishtail and ball-nose. ENTITY bullnose_endmill SUBTYPE OF.

End Mills The Essential Beginners Guide

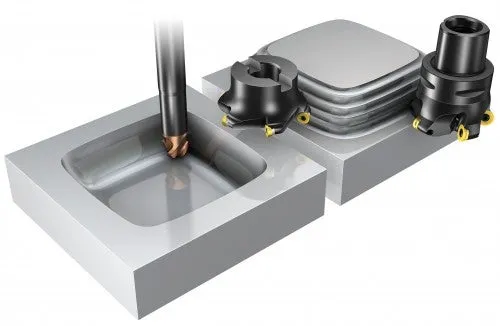

Moulds dies and blades milling are usual examples of this category.

. Each end mill has flutes on its cutting head that carry chips away from the workpiece to prevent damage to the end mill or workpiece. So I dont know if its a problem with the pass or the tool definition to make that work. These milling bits may also be used in mold profiling applications with greater productivity than ball end mills.

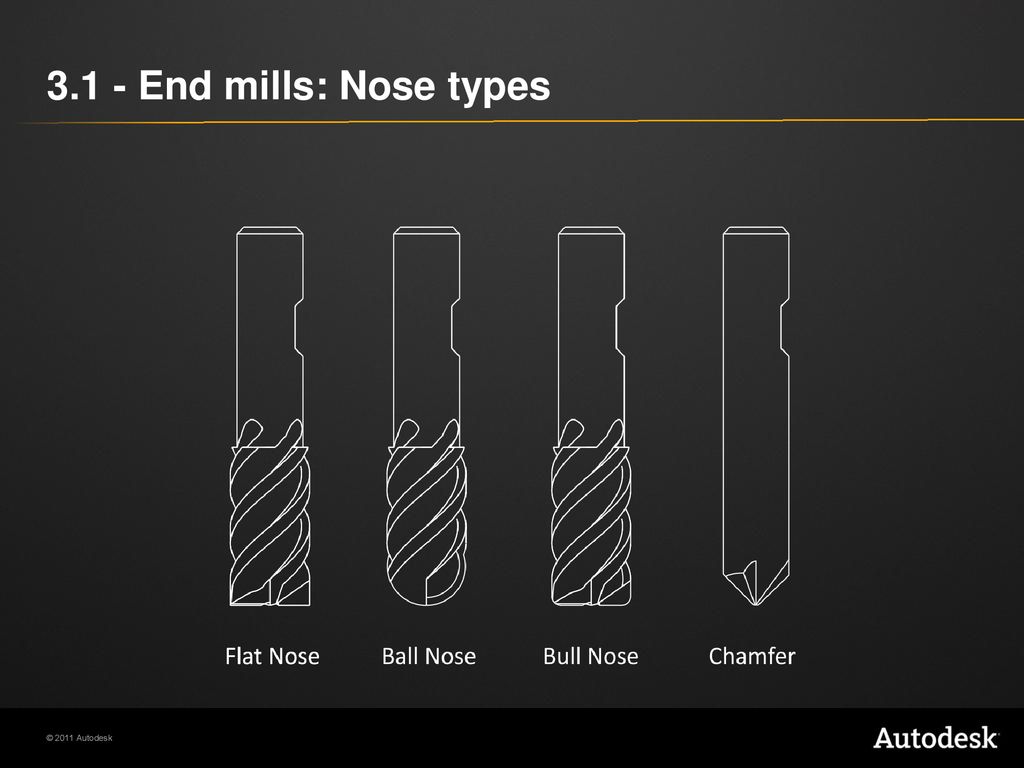

The term bullnose originates from the rounded nose of a bull. Defining a chamfered end mill December 17 2008 0926 AM Were looking to have the ability to define an end mill with a chamfer instead of a radius bull nose tip. Ball-end or bull-nose end mills are mainly used for copying operations of complex surfaces the application being known as sculptured surface milling SSM.

Shank type - Straight shank and Brown and Sharpe or Morse Taper shank. The ball has a radius with its center point at the center of the end mill. A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds.

Ugly way to go about it. Bull Nose EIBSquareBullnose 49 Toroid TOIToroid 49 Solid Carbide End Mill Program Tool Contents 41 Solid Carbide End Mills Millstars new High Performance and ultra-precise solid carbide end mills were designed for high speed high velocity and hard steel milling. Bull-Nose Corner Radius End Mill.

Sometimes called bull-nose end mills they are rotated against a workpiece to create a flat-bottomed groove with slightly rounded inside corners in milling applications that require a specific radius. These radius end mills are single ended tools used for making corner radii at the bottom of a milled shoulder. This type of tooling features flutes with no flat bottom rounded off at the end creating a ball nose at the tip of the tool.

Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing. Bull end mills are simply corner radius end mill cutters. EXISTSSELFedge_radius AND EXISTSSELFeffective_cutting_diameter AND SELFedge_radius SELFeffective_cutting_diameter2.

These have a flat bottom but rounded corners so you can have a filleted inner corner while also. Also called corner radius end mills this type of cutter is a combination of fishtail and ball-nose also a flat bottom but with rounded corners. In the meantime tbaker the only compromise is to define it as a bullnose with the chord length of the bull radius matching the chamfer length.

When using a ball nose end mill the most critical area of the cutting edge is the tool centre where the cutting speed is close to zero which is unfavourable for the cutting process. Bull-nose end mills. These radius end mills are single ended tools used for making corner radii at the bottom of a milled shoulder.

A ball nose end mill also known as a spherical end mill or ball end mill has a semisphere at the tool end. Ball nose end mills or ball end cutters are constructed with a round cutting end and center cutting edges used for milling contoured surfaces slotting and pocketing. Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations.

Ball nose mills have a radius at the bottom which makes for a nicer surface finish in your workpiece meaning less work for you as the piece wont need to be finished any further. Bull Nose End Mills Corner Radius Bull end mills are simply corner radius end mill cutters. They are usually made from high speed steel or cemented carbide and have one or more flutes.

Meaning the flat on the bottom of the tool is the same diameter. What is a bull nose end mill. Mechanics of wavy-edge bull-nose helical end mill A photograph of the investigated WEBNHE is shown in Fig.

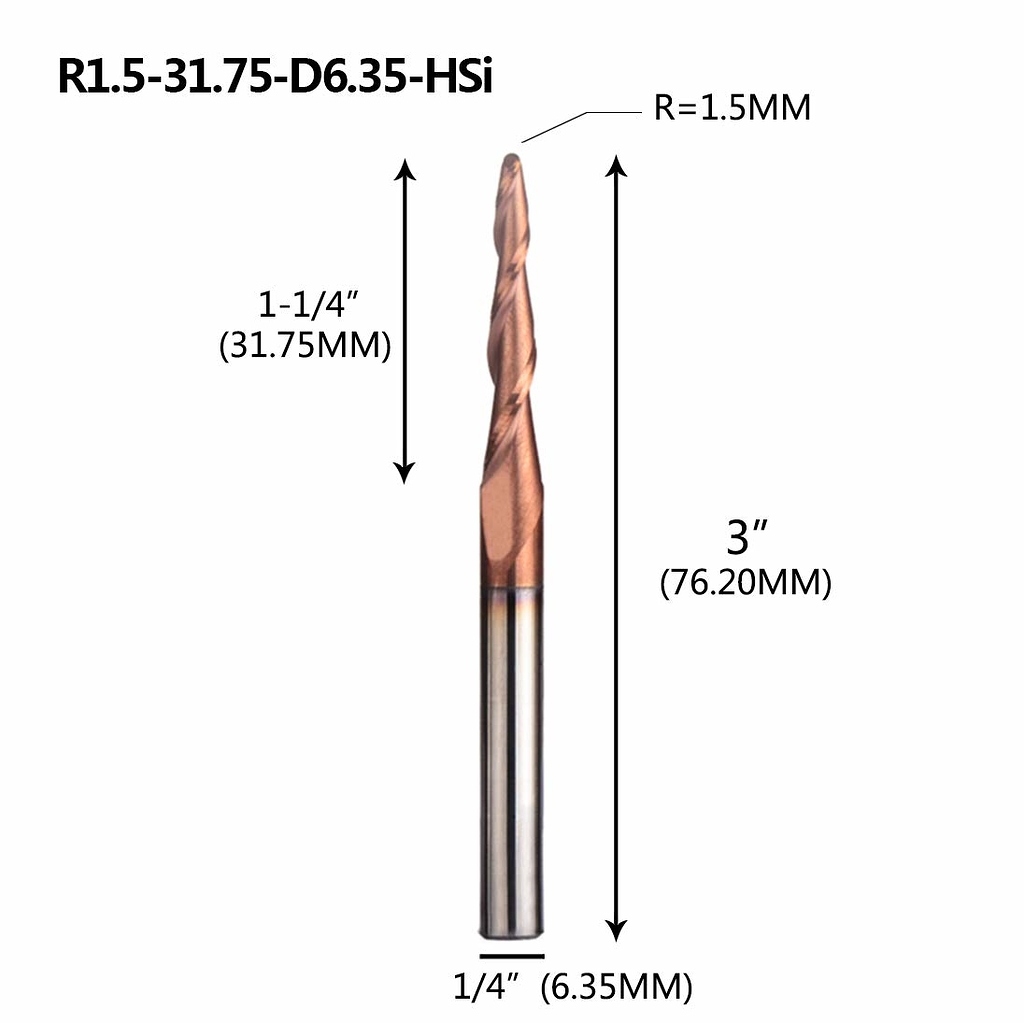

Explicit Attributes Entity bullnose_endmill has the following local and inherited explicit attributes. They only way we seem to be able to come close is using a conical mill zeroing out the radius and redefing the conical portion as a chamfer. Ball nose end mills are used on workpieces with complex surfaces.

Bull-nose end mills are often used to mill molds plastic injection molds die cast molds etc. Theyre also known as taper degree end mills. Citation needed See also.

A bullnose clarification needed is used in highway construction in North America to buffer and protect the end of the crash barrier or Jersey barrier at entrance and exit ramps. A tool with larger radii can also be referred to as bull nose Ball Profile End Mills. A ball end mill is not the same as a corner radiusbull nose end mill.

Configuration of end profile - Flat Chamfer Radius Ball Taper Bull Nose end mills and their combinations 2. A ball end mill will determine the characteristics of the. 625 shows WEBNHE performing up milling operation.

Its just another version of a bull-nose end mill. They are used for contour milling shallow slotting pocketing and contouring applications. The words end mill are generally used to refer to flat bottomed cutters but also include rounded cutters referred to as ball nosed and radiused cutters referred to as bull nose or torus.

Chip evacuation at the tool centre is critical due to the narrow space at the chisel edge. They are the most common tool used in a vertical mill. Made of solid carbide theyre harder stronger and more wear resistant than high-speed steel for the longest life and best finish on hard material.

Ball end cutters are usually made from carbide steel or other high-speed steel composition. Additionally a smaller diameter ball nose mill can also be used in engraving. Corner radius end mill cutters have a stronger milling edge than square end mills so feed rates may be increased and yield longer tool life and greater productivity.

The cutter diameter is often the first thing machinists look for when choosing a tool for their job. Choosing flat end mill vs.

Basic End Mills Technical Information Msc Industrial Supply Co

General Tool Geometry And Surfaces Of The Various End Mills A General Download Scientific Diagram

Estlcam Confused Adding A Tapered Ball Nose Bit Advice V1 Engineering Forum

Basic End Mills Technical Information Msc Industrial Supply Co

End Mill An Overview Sciencedirect Topics

Types Of End Mills Difference Between End Mill And Drill Bit What Is End Milling Cnclathing

End Mill Featurecam Products Autodesk Knowledge Network

Immersion Angle Cutting Force Components Cutting Width And Chip Load Download Scientific Diagram

Ball End Mill An Overview Sciencedirect Topics

End Mill An Overview Sciencedirect Topics

End Mill An Overview Sciencedirect Topics

End Mills The Essential Beginners Guide

Test Part Machining Left Bull Nose End Mill With Corner Radius And Download Scientific Diagram